The world of textile manufacturing is undergoing a quiet revolution, one that marries ancient craftsmanship with cutting-edge digital technology. At the heart of this transformation lies the digital jacquard loom, a modern reinterpretation of the traditional kesi (Chinese tapestry) weaving technique. These sophisticated machines are redefining what's possible in textile design and production, breathing new life into an art form that dates back over 2,500 years.

The digital jacquard loom represents a remarkable fusion of heritage and innovation. Unlike conventional weaving methods that rely on physical pattern cards or manual manipulation, these computer-controlled systems translate intricate digital designs directly into woven fabric. The process maintains the essential characteristic of kesi - the ability to create discontinuous wefts that form complex patterns - while eliminating many of the limitations that made traditional kesi production so labor-intensive.

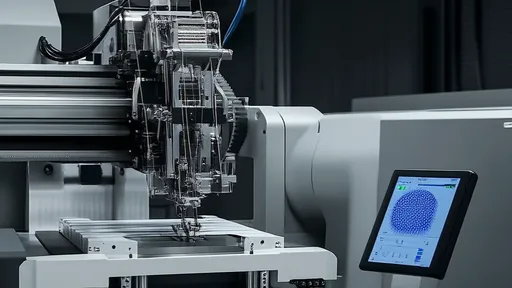

What makes these machines particularly groundbreaking is their implementation of true warp-separation technology. The loom's sophisticated mechanism controls each individual warp thread with precision, allowing for the creation of patterns with photographic detail. This level of control enables weavers to produce designs that would have been unimaginable with traditional techniques, where pattern complexity was limited by the weaver's skill and patience.

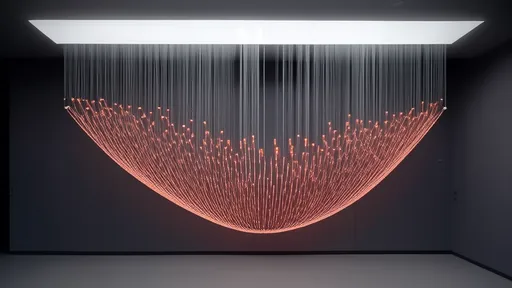

The impact of digital jacquard technology extends far beyond mere production efficiency. Designers now enjoy unprecedented creative freedom, able to experiment with complex gradients, photographic imagery, and intricate geometric patterns that would have required months of painstaking handwork in the past. The digital workflow allows for rapid prototyping and iteration, significantly shortening the design-to-production cycle while maintaining the distinctive textural qualities that make kesi fabrics so valued.

One of the most significant advantages of digital jacquard looms is their ability to preserve traditional aesthetics while modernizing production. The characteristic "carved" appearance of kesi - created by the slight gaps between color areas - is faithfully reproduced by the machine's precise control of weft insertion. This attention to maintaining the visual language of traditional kesi ensures that digitally-produced pieces retain the cultural authenticity that collectors and connoisseurs expect.

From a technical perspective, the operation of these looms is nothing short of remarkable. High-precision servo motors control the movement of thousands of warp threads simultaneously, while advanced software algorithms calculate the most efficient weft insertion patterns. The system's ability to handle multiple weft colors simultaneously - a feature inspired by traditional kesi techniques - allows for the creation of richly layered designs without the need for frequent thread changes.

The adoption of digital jacquard technology is having profound implications for the preservation of textile heritage. By dramatically reducing the time and skill required to produce complex patterns, these machines are making kesi weaving more accessible to a new generation of artisans. Traditional weaving studios are finding that digital tools allow them to take on more ambitious projects while maintaining the essence of their craft, ensuring the continuation of kesi traditions in the digital age.

Quality control has reached new heights with digital jacquard systems. Integrated vision systems can detect and correct minute weaving errors in real-time, ensuring consistency across long production runs. This level of precision is particularly valuable for restoration work, where exact replication of historical patterns is often required. Museums and conservation teams are increasingly turning to digital jacquard technology to recreate damaged sections of antique textiles with unprecedented accuracy.

As the technology continues to evolve, we're seeing exciting developments in material compatibility. Modern digital jacquard looms can handle everything from fine silks (traditional kesi material) to metallic threads and even unconventional materials like conductive fibers. This versatility is opening up new possibilities for functional textiles that combine aesthetic appeal with technical performance, from smart clothing to architectural fabrics.

The environmental benefits of digital jacquard weaving shouldn't be overlooked. By optimizing thread usage and minimizing waste, these systems represent a more sustainable approach to textile production. The precision of digital control means that exact amounts of each colored weft are used, reducing the leftover thread that's common in traditional weaving. Additionally, the ability to perfect designs digitally before production begins significantly cuts down on material waste from trial runs.

Looking to the future, the integration of AI with digital jacquard technology promises to further revolutionize the field. Machine learning algorithms are being developed that can analyze historical textile patterns and generate new designs that stay true to traditional aesthetics while introducing innovative elements. This symbiotic relationship between human creativity and artificial intelligence is creating exciting new possibilities for textile design that honor the past while embracing the future.

Educational institutions are rapidly incorporating digital jacquard technology into their textile programs, recognizing its importance as both a preservation tool and a platform for innovation. Students now learn to navigate between traditional hand-weaving techniques and digital design interfaces, developing a hybrid skill set that prepares them for the evolving demands of the textile industry. This dual focus ensures that the deep knowledge of traditional techniques isn't lost as the field modernizes.

The commercial implications of digital jacquard weaving are significant. While hand-woven kesi pieces will always hold special value for collectors, digitally-produced versions make these intricate textiles accessible to a broader market. Luxury brands are particularly interested in this technology, as it allows them to incorporate kesi-inspired designs into their collections at different price points without compromising on quality or aesthetic integrity.

Perhaps most importantly, digital jacquard technology is changing our relationship with traditional crafts. By removing some of the technical barriers to entry, these systems are democratizing access to textile arts while maintaining respect for traditional skills. The result is a vibrant ecosystem where master weavers, digital designers, and newcomers to the craft can all contribute to the evolution of kesi weaving, ensuring its relevance in the 21st century and beyond.

As digital jacquard looms become more sophisticated and accessible, we're witnessing the emergence of a new chapter in textile history. One where the precision of digital technology serves not to replace traditional craftsmanship, but to extend its possibilities. The "warp and weft" of innovation and heritage are being woven together in ways that honor the past while creating exciting new futures for textile arts.

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025