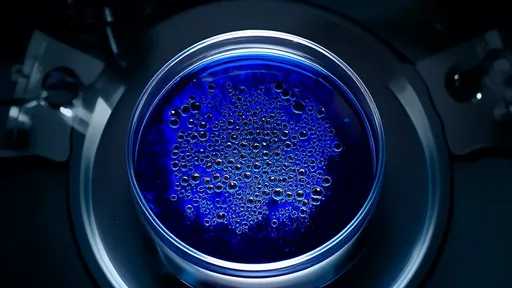

The ancient art of blue-and-white porcelain has entered a revolutionary new phase with the development of electrolytic glaze techniques that allow unprecedented control over cobalt diffusion patterns. For centuries, ceramic artists have sought to master the unpredictable beauty of cobalt oxide's bleeding effects in glaze, but modern electrochemical methods are now transforming this traditional craft into a precise science.

At the heart of this innovation lies the application of controlled electric currents during the glaze firing process. When a voltage is applied across the glazed ceramic surface, the mobility of cobalt ions becomes directly responsive to the electrical field. This phenomenon enables artisans to guide the characteristic "bleeding" of cobalt blue in ways that were previously impossible through traditional kiln techniques alone.

The Science Behind the Technique

Traditional blue-and-white porcelain relies on the natural tendency of cobalt oxide to diffuse through molten glaze during firing. The organic binder burns away, leaving cobalt particles that melt and spread, creating those distinctive soft-edged blue patterns. In the electrolytic method, electrodes are strategically placed in contact with the glazed surface before firing. As the kiln temperature rises and the glaze becomes conductive, the applied current begins influencing ion migration.

Cobalt ions (Co²⁺), being positively charged, migrate toward the cathode in this system. The degree of migration depends on three key factors: current density, glaze viscosity at various temperatures, and firing duration. By carefully modulating these parameters, artisans can produce everything from subtle gradient effects to dramatic directional veining that appears to flow across the ceramic surface.

Technical Considerations in Electrolytic Glazing

Successful implementation requires specialized glaze formulations with controlled electrical conductivity. The base glaze must contain sufficient mobile ions (typically alkali metal ions) to carry current before the cobalt becomes mobile at higher temperatures. Many practitioners use modified versions of traditional lime-alkali glazes with added fluxes to maintain appropriate conductivity throughout the firing cycle.

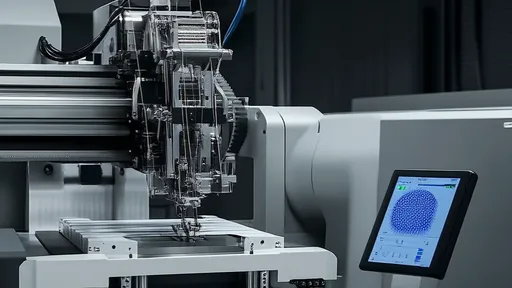

The positioning of electrodes proves equally crucial. Common configurations include concentric rings for radial patterns, parallel plates for linear gradients, or even shaped electrodes that create specific diffusion fields. Some advanced setups employ multiple independently controlled electrodes to produce complex interference patterns in the cobalt distribution.

Firing schedules must be carefully coordinated with electrical parameters. Typically, voltage application begins when the glaze reaches about 600°C (where ionic conductivity becomes significant) and continues through peak temperature (usually 1250-1300°C for most blue-and-white ware). The most striking effects often occur during the cooling phase, where controlled current can actually "freeze" the cobalt in mid-diffusion, creating unique arrested-flow patterns.

Artistic Possibilities Unleashed

This technology has opened remarkable creative avenues for contemporary ceramic artists. The ability to "draw" with electric fields allows for precision unattainable with brushwork alone. Some practitioners create electric field maps that correspond to traditional Chinese landscape paintings, with cobalt accumulating in areas that would receive ink washes. Others use the technique to produce photorealistic gradations reminiscent of watercolor techniques.

Particularly stunning are the "electric bloom" effects, where alternating currents cause rhythmic banding in the cobalt distribution. These patterns resemble natural mineral formations or the growth rings of trees. When combined with resist techniques that limit glaze contact in certain areas, artists can produce crisp outlines that gradually dissolve into controlled bleeds - a previously impossible combination in underglaze decoration.

Historical Context and Modern Revival

The marriage of electricity and ceramics isn't entirely new. Electrolytic glaze effects were first observed accidentally in early 20th century industrial ceramics, when misfired electrical insulators displayed unusual coloration patterns. However, these phenomena weren't systematically studied for artistic purposes until the 1990s, when ceramic engineers began collaborating with studio potters to harness these effects intentionally.

Contemporary artists like Zhang Liwei have pushed the boundaries of this medium, creating large-scale installations where the electrical parameters change dynamically during firing based on sensor inputs. His piece "Azure Currents" used temperature-dependent voltage adjustments to mimic the flow of the Yangtze River across a porcelain landscape.

Challenges and Limitations

While promising, the technique presents several practical challenges. The high-temperature electrodes require specialized materials that can withstand both the kiln environment and react minimally with the glaze. Platinum-rhodium alloys work well but prove prohibitively expensive for many artists. Some experimenters have developed successful carbon-based alternatives, though these limit firing atmospheres to reduction.

Glaze chemistry requires precise balancing - too many mobile ions creates excessive current leakage and weak effects, while too few prevents adequate control. The interaction between electric fields and other colorants (like iron or copper) remains poorly understood, limiting palettes in many cases to cobalt-dominated schemes.

Perhaps most significantly, the process demands rigorous process control. Small variations in kiln atmosphere, temperature distribution, or glaze thickness can dramatically alter outcomes. Many artists maintain detailed logs of electrical parameters correlated with final appearances, building proprietary "libraries" of effects through extensive testing.

Future Directions

Research continues on several fronts. Materials scientists are developing smart glazes with temperature-dependent conductivity profiles that allow different control regimes at various firing stages. Some experimenters are exploring pulsed current techniques that create oscillating diffusion fronts for unique pattern generation.

Perhaps most intriguing is work on computer-controlled multi-electrode arrays that can "write" directly in cobalt diffusion during firing. Early prototypes show promise for creating detailed imagery without any physical surface contact - essentially "drawing with electricity" in the glaze matrix itself.

As the technique matures, it may bridge the ancient and modern in unprecedented ways. The distinctive blue that has captivated collectors since the Yuan dynasty now meets twenty-first century control technologies, ensuring blue-and-white porcelain continues evolving while maintaining its timeless aesthetic appeal. This fusion of heritage and innovation promises to keep Chinese porcelain at the forefront of global ceramic arts for generations to come.

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025

By /Jul 23, 2025